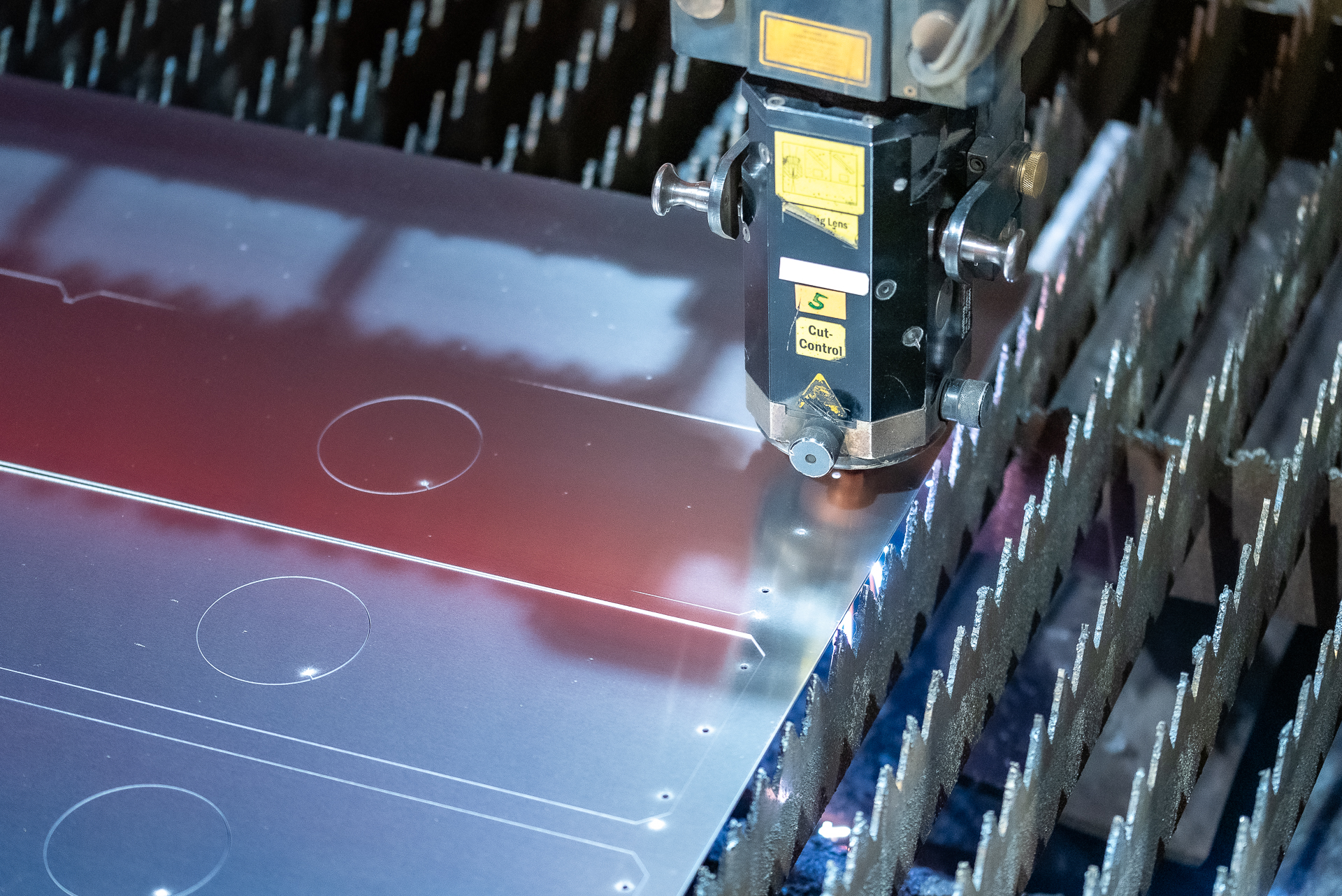

LVD Fiberlaser

LVD Phoenix

10kw Fiberlaser

LVD Fiberlaser

- Downloads

- LVD Fiberlaser

LVD Fiberlaser

The LVD Phoenix 10kW fiber laser is equipped with a 10kW IPG fiber laser featuring automatic point focusing and diameter adjustment for easier cutting across various thicknesses, ensuring perfect cuts. The fiber can cut ferrous materials like black steel, duplex, and stainless steel, as well as non-ferrous materials such as aluminum, copper, and brass. The laser comes with a fully automatic lens change system tailored to the type of material and thickness being cut. A fully integrated Siemens CNC control and drive system ensure maximum utilization and precision.